In the fast-evolving landscape of advanced manufacturing, precision, quality, and sustainability are no longer optional—they’re essential. One of the persistent challenges in metal-based manufacturing processes is dealing with residual aluminum, a byproduct that can compromise both the integrity and efficiency of systems. Understanding the science behind reducing residual aluminum can help manufacturers enhance product quality, reduce waste, and extend equipment life.

What is Residual Aluminum?

Residual aluminum refers to unwanted aluminum remnants left behind after casting, forming, machining, or welding operations. This leftover material can settle in tooling systems, mold cavities, or even on finished surfaces, interfering with subsequent processing or degrading product quality.

In many cases, residual aluminum arises due to:

- Incomplete melting or fusion during casting

- Surface oxidation forming aluminum oxide (Al₂O₃) films

- Poor separation techniques during alloy refinement

- Inefficient material flow during extrusion or die casting

Regardless of the source, its presence is undesirable and managing it effectively has become a scientific and engineering priority.

Why Reducing Residual Aluminum Matters

The presence of residual aluminum can cause a cascade of problems:

- Surface defects: It can lead to pitting, uneven finishes, or delamination.

- Tool wear: Accumulation in machinery can accelerate wear and require frequent maintenance.

- Contamination: Residuals can contaminate other materials, especially in multi-alloy systems.

- Structural integrity issues: In aerospace or automotive applications, even minor impurities can lead to failure under stress.

The Metallurgical Science of Residue Formation

To address the issue, it’s important to understand how aluminum behaves in various manufacturing contexts:

1. Aluminum’s Reactivity

Aluminum readily reacts with oxygen, forming a passive oxide layer. While this layer protects the metal in normal conditions, in manufacturing, it becomes a problem. The oxide film is often insoluble in molten metal and can remain as inclusions in final products.

2. Thermal Characteristics

Aluminum’s melting point (660.3°C) and high thermal conductivity make it a fast-melting but challenging material to control in terms of flow and solidification. Residue often forms when heat gradients cause premature cooling in certain zones, trapping unmelted or partially melted particles.

3. Alloy Composition

Alloying elements like silicon, magnesium, or copper can interact with aluminum to either increase or decrease residue depending on their reactivity and solidification properties.

Scientific Approaches to Reducing Residual Aluminum

Reducing residual aluminum involves both preventative strategies and post-process treatments. Here’s how science plays a critical role:

1. Advanced Material Separation Techniques

Modern refining processes such as electromagnetic stirring, flux treatment, and vacuum degassing help separate impurities and reduce aluminum inclusions. These techniques manipulate the behavior of aluminum at the microscopic level, improving purity.

2. Controlled Atmospheres

Using inert gas environments (e.g., argon or nitrogen) during melting or casting can drastically reduce oxidation, thereby minimizing the formation of aluminum oxide residues.

3. Precision Temperature Control

Advanced thermal management, including induction heating and thermographic monitoring, helps maintain uniform temperature profiles. This minimizes cold spots and incomplete melts, a primary cause of residual aluminum.

4. Tooling Surface Engineering

Coatings such as titanium nitride or ceramic composites on dies and molds prevent aluminum adhesion and reduce the likelihood of residue sticking to tooling surfaces.

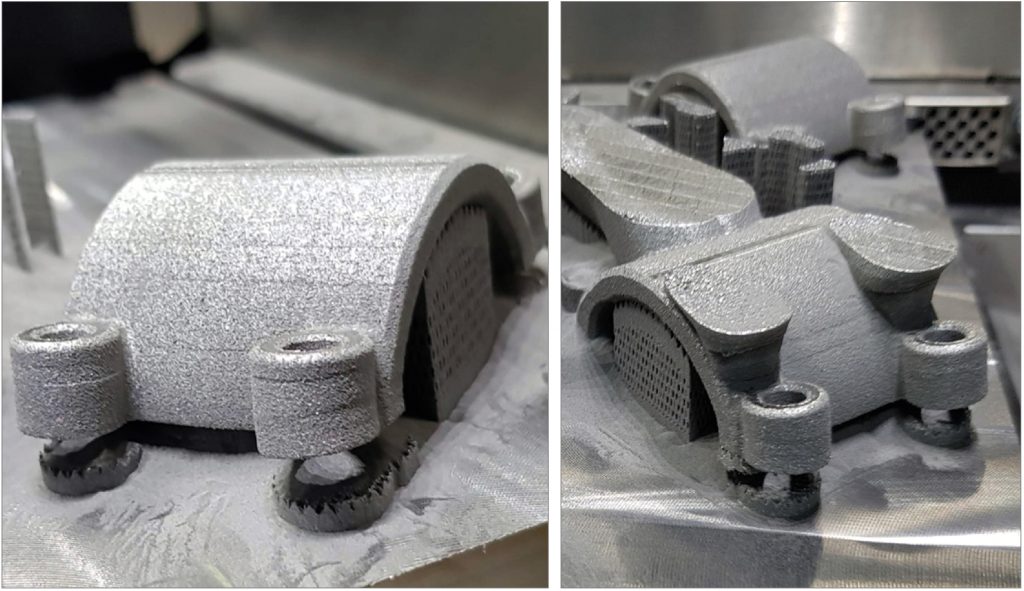

5. Additive Techniques

In some cases, the use of grain refiners or modifiers can alter the solidification dynamics of aluminum alloys, promoting a cleaner microstructure with fewer trapped inclusions.

Data-Driven Solutions: The Role of AI and Simulation

Modern manufacturing increasingly relies on data analytics and machine learning to predict and minimize residual aluminum formation. By simulating fluid dynamics, thermal gradients, and solidification patterns, manufacturers can anticipate residue-prone zones and adjust parameters in real time.

For example, computational fluid dynamics (CFD) can model how molten aluminum flows through complex die geometries. Combined with machine vision systems, these models can help detect anomalies early and implement corrections proactively.

Sustainability Implications

From a sustainability standpoint, reducing residual aluminum means:

- Less rework and scrap generation

- Lower energy consumption during remelting

- Extended lifespan of tooling and equipment

- Fewer toxic byproducts like aluminum dross and slag

This not only improves environmental performance but also contributes to cost savings and circular manufacturing practices.

Final Thoughts

Reducing residual aluminum is more than just a quality control measure—it’s a scientific endeavor rooted in metallurgy, thermodynamics, and process engineering. By embracing advanced technologies and data-driven insights, manufacturers can tackle this invisible adversary head-on, leading to stronger products, smarter systems, and a more sustainable future.