In the rapidly evolving world of manufacturing, precision, efficiency, and flexibility have become crucial factors for success. One technology that has revolutionized the manufacturing landscape is CNC machining. CNC machining services offer manufacturers a reliable way to produce complex, high-quality parts with exceptional accuracy and consistency. This guide will explore everything manufacturers need to know about CNC machining services, from the basics to the benefits and applications.

What is CNC Machining?

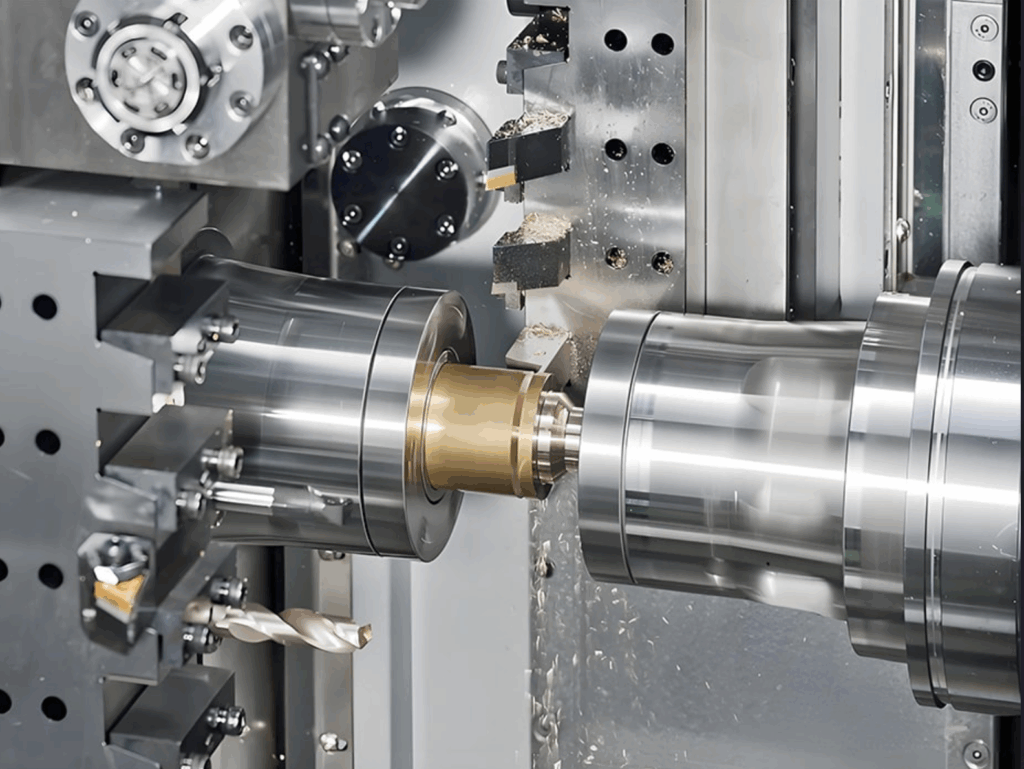

CNC stands for Computer Numerical Control. CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. Unlike traditional machining, where operators manually control the tools, CNC machining automates the entire process. This automation allows for highly precise cuts, shaping, and finishing of metal, plastic, and other materials.

CNC machines include mills, lathes, routers, and grinders that are controlled by a computer. The computer follows detailed instructions from a CAD (Computer-Aided Design) file, turning raw materials into finished parts with minimal human intervention.

Types of CNC Machining Services

Manufacturers can access various CNC machining services depending on their specific needs:

CNC Milling

CNC milling involves rotating cutting tools that remove material from a stationary workpiece. This method is excellent for creating complex shapes, holes, and contours. It is widely used for prototyping and production runs in industries such as aerospace and automotive.

CNC Turning

In CNC turning, the workpiece rotates while a stationary cutting tool shapes it. This process is ideal for producing cylindrical parts like shafts, bolts, and screws with precise dimensions.

CNC Drilling

CNC drilling services specialize in creating accurate holes in a material. This is often combined with other machining processes to complete a part.

CNC Grinding

This process uses an abrasive wheel to finish a surface to a high degree of accuracy and smoothness. CNC grinding is essential for parts that require tight tolerances and excellent surface finishes.

Advantages of CNC Machining Services

CNC machining services offer several key benefits that have made them a preferred choice for manufacturers worldwide:

Precision and Accuracy

One of the most significant advantages of CNC machining is its ability to produce parts with tight tolerances and consistent quality. The computer-controlled process eliminates human error, ensuring every piece is manufactured to exact specifications.

Efficiency and Speed

CNC machines can operate continuously 24/7 with minimal supervision, significantly speeding up production times. They also reduce the need for multiple setups, which streamlines the manufacturing process.

Flexibility

With CNC machining services, manufacturers can easily switch between different designs or make adjustments by simply changing the software program. This flexibility is especially useful for custom or small-batch production.

Cost-Effectiveness

Although the initial investment in CNC machinery and programming can be high, the overall cost per part is usually lower compared to manual machining. Reduced waste, less rework, and faster production contribute to cost savings.

Complex Geometry

CNC machining can produce parts with intricate details that would be difficult or impossible to achieve with manual processes. This capability is crucial for advanced industries such as aerospace, medical devices, and electronics.

Common Materials Used in CNC Machining

CNC machining services are compatible with a wide range of materials. Some of the most commonly machined materials include:

- Metals: aluminum, stainless steel, brass, titanium, copper

- Plastics: ABS, polycarbonate, nylon, acrylic, PEEK

- Composites and specialty materials for specific applications

The choice of material depends on the part’s intended function, mechanical properties, and budget.

Applications of CNC Machining Services

CNC machining plays a vital role in multiple industries, supporting both prototyping and full-scale production:

Aerospace

The aerospace industry demands high-precision, lightweight parts that can withstand extreme conditions. CNC machining services provide components like turbine blades, engine parts, and structural components with exact tolerances.

Automotive

From engine blocks to custom gear components, CNC machining helps automotive manufacturers produce durable and reliable parts that improve vehicle performance.

Medical Devices

Medical equipment requires components with high precision and biocompatibility. CNC machining services can create surgical instruments, implants, and diagnostic equipment parts with outstanding accuracy.

Electronics

The electronics sector benefits from CNC machining for producing cases, connectors, and heat sinks, ensuring components fit perfectly within tight design specifications.

Industrial Equipment

Heavy machinery and industrial tools require robust and precisely machined parts that can endure heavy use, all achievable through CNC machining.

Choosing the Right CNC Machining Service Provider

Selecting the appropriate CNC machining service is critical to ensuring product quality and timely delivery. Manufacturers should consider several factors:

- Experience and expertise in machining the required materials

- Range of available CNC machines and capabilities

- Quality control processes and certifications

- Turnaround time and production capacity

- Communication and technical support

A trusted service provider will work closely with manufacturers to understand project requirements and offer solutions that optimize cost and efficiency.

The Future of CNC Machining Services

As manufacturing continues to advance, CNC machining services are evolving with new technologies. Integration with Industry 4.0, including IoT (Internet of Things) connectivity, machine learning, and automation, is enhancing machine performance and predictive maintenance. Additionally, the use of advanced materials and multi-axis machining is expanding the possibilities for complex designs.

Additive manufacturing (3D printing) is also beginning to complement CNC machining by enabling rapid prototyping and hybrid manufacturing processes. Together, these innovations will continue to drive productivity and innovation in manufacturing.

Conclusion

CNC machining services have transformed the manufacturing industry by offering unmatched precision, speed, and versatility. For manufacturers seeking high-quality parts with complex geometries, CNC machining provides an efficient and reliable solution. Understanding the types, benefits, and applications of CNC machining enables manufacturers to leverage this technology to improve production, reduce costs, and maintain competitive advantages in their markets.